How to Identify the Fiber Color Code?

We have been using different types of fiber optic cable in labs and data centers for years. It is not unusual for a green hand to mix up the 50/125 and 62.5/125 multimode fibers, or the single mode fibers, not to mention the multi-fiber cables that may consist of tens and hundreds of fibers. Fortunately, there are systems made to address these issues, such as the EIA/TIA-598, which is the most recognized system worldwide. It includes fiber color code for different types and numbers of optical fiber cables. These fiber optic cable color codes help us to identify an optical fiber cable from its jacket, buffer, tube, connector, etc.

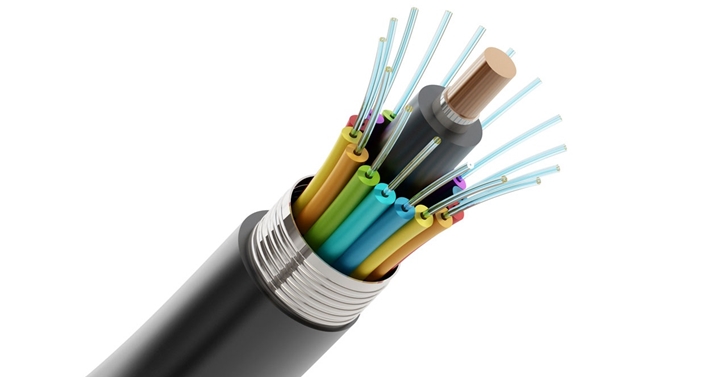

Figure 1: Colored jackets of multi-fiber cable.

Outer Jacket Color Code

Colored outer jackets or print may be used on outside plant and premises fiber cables, e.g., fiber distribution cables, fiber optic patch cords, etc. In EIA/TIA-598, the fiber color code defines the jacket color codes for different fiber types. So for optical fiber cable that contains only one type of fiber we can easily identify it by its jacket color; unless otherwise specified, the outer jacket of premises cable containing more than one fiber type shall use a printed legend to identify the quantities and types of fibers within the cable, for example "12 Fiber 8 x 50/125, 4 x 62.5/125." Here are the jacket color codes for different fiber types:

| Fiber Type | Color Code | ||

|---|---|---|---|

| Non-military Applications | Military Applications | Suggested Print Nomenclature | |

| OM1 62.5/125µm Multimode | Orange | Slate | 62.5/125 |

| OM2 50/125µm Multimode | Orange | Orange | 50/125 |

| OM3 50/125 µm (850 nm Laser-Optimized) Multimode | Aqua | Undefined | 850 LO 50/125 |

| OM4 50/125µm (850 nm Laser-Optimized) Multimode | Aqua/Violet | Undefined | 850 LO 50/125 |

| 100/140µm Multimode | Orange | Green | 100/140 |

| OS1/OS2 Single Mode | Yellow | Yellow | SM/NZDS, SM |

| Polarization Maintaining Single Mode | Blue | Undefined | Undefined |

Besides the jacket colors specified in fiber color code standard, other colors may also be used if the print on the outer jacket can tell the fiber classifications. Such colors should be agreed upon between manufacturer and user.

Inner Cable Organizational Fiber Color Code

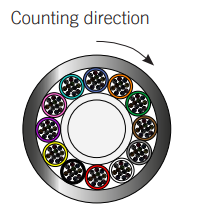

Inside a multi-fiber cable, individual fibers are compliant to fiber color code as well. They are often distinguished from one another by color-coded jackets, buffers or tubes on each fiber. According to EIA/TIA-598, inner fibers are color coded in a group of 12 fibers and they are counted in a clockwise direction.

Figure 2: Counting direction of a group of 12 fibers.

There are two situations for multi-fiber cables:

The color sequence for inner fibers is as follows:

| Fiber Position | Jacket Color | Fiber Position | Jacket Color |

|---|---|---|---|

| 1 | Blue | 13 | Blue with black tracer |

| 2 | Orange | 14 | Orange with balck tracer |

| 3 | Green | 15 | Green with black tracer |

| 4 | Brown | 16 | Brown with black tracer |

| 5 | Slate | 17 | Slate with black tracer |

| 6 | White | 18 | White with black tracer |

| 7 | Red | 19 | Red with black tracer |

| 8 | Black | 20 | Black with yellow tracer |

| 9 | Yellow | 21 | Yellow with black tracer |

| 10 | Violet | 22 | Violet with black tracer |

| 11 | Rose | 23 | Rose with black tracer |

| 12 | Aqua | 24 | Aqua with black tracer |

| Jacket color images are By User: Venge, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=64098042 | |||

Connector Color Code

Connectors are also a part of the fiber color code. Since there are different polish styles of fiber end-face, the connectors of fiber jumpers and the mating adapters are color coded for identification. However, the advent of metallic connectors like the FC and ST made connector color coding difficult, so colored strain relief boots are also used. The boot color may vary among manufacturers.

| Fiber Types | Polish Style | Connector Body | Strain Relief/Mating Adapter |

|---|---|---|---|

| OM1 62.5/125 | UPC | Beige/Grey | Beige/Grey |

| OM2 50/125 | UPC | Black | Black |

| OM3/OM4 50/125 laser optimized | UPC | Aqua | Aqua |

| Single Mode | UPC | Blue | Blue |

| Single Mode | APC | Green | Green |

Conclusion

Fiber optic cable color code is a system that helps us distinguish fiber types visually from the colored fiber jacket, fiber connector, fiber boot, etc. The optical fiber color coding is also practical for fiber optic engineers during splicing, because the colorful fibers also help ensure the continuity of color codes throughout a cable run. Thus, fiber cable color coding is essential to fiber optic communications like the twisted pair color coding to copper wiring systems.

Comments

Post a Comment